A look into fresh fibre paperboard

Fresh fibre paperboards help match the most stringent requirements for cleanliness, transparency, and sustainability, as Johan Granås, Holmen Iggesund’s head of sustainability, explains.

Why is fresh fibre paperboard such a good choice when it comes to cosmetic packaging and “clean” products?

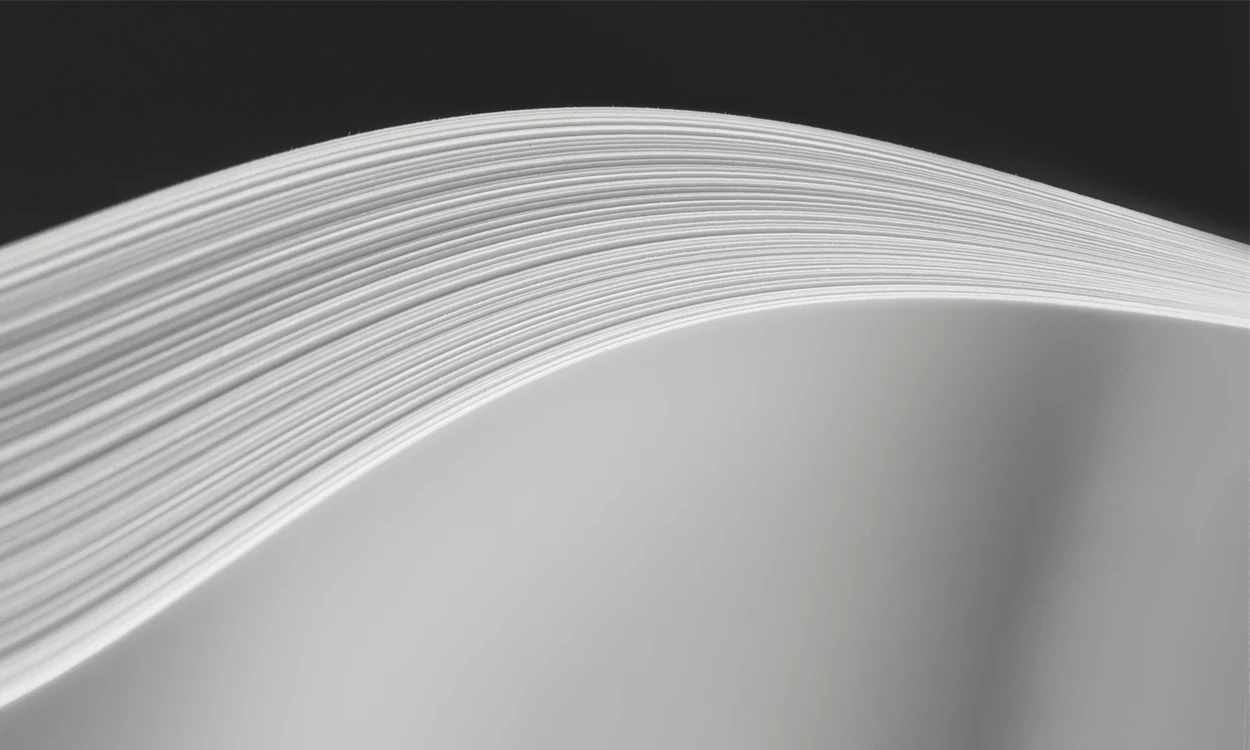

Fresh fibre paperboard is a clean product produced simply from wood that comes from the forest. Fresh fibre paperboard looks pristine, keeps its shade and whiteness over time, and is less prone to cracking than recycled paperboards. There are also no issues with contamination from inks and other residues. These are all important aspects for cosmetic products.

Clean beauty brands are prioritising recyclable or compostable packaging whenever possible. What role does fresh fibre play here?

Fresh fibre is ideal for recycling. In fact, without a steady input of fresh fibre, there would be no recycled paperboard.

At Holmen we promote recycling over composting as the fibres can be reused again and again. Composting is more suitable when recycling is no longer feasible, such as in food packaging when paperboard is contaminated with grease.

Johan Granås,

Head of sustainability at

Holmen Iggesund Paperboard.

What is Holmen Iggesund doing to further improve the “cleanliness” of its products?

Our paperboard is made of local wood, water, and energy. Holmen uses only the pure cellulose from wood and with Invercote we take it even a step further using a manufacturing process that singles out the individual cellulose fibres from the wood. The remaining parts of the tree are used to power the whole mill, enabling us to run solely on biopower. The wood used for Invercote comes from certified sustainably managed nearby forests. Our water comes from a nearby lake, and we reuse it as much as we can – around 30 times before the water is cleaned and returned to nature.

And, because we want our products to remain as pure as possible, we are in constant dialogue with our suppliers in order to improve the purity of their products and processes, for example in the pigments for our coatings. The chemicals used in our own processes are recovered and reused again and again and we are continually looking for improvements to make all processes and products as pure as possible.

Transparency and traceability are very important to us. Brand owners or anyone interested can come and visit us in Iggesund and see for themselves where their sustainable packaging material comes from and how it is manufactured!

Created 21 September, 2020.